Wooden Pattern

Our wooden pattern service is dedicated to creating intricate and precise patterns used in the casting process. Skilled craftsmen meticulously craft wooden patterns that serve as the molds for casting various components, taking into account the specific dimensions, shapes and intricacies required for the final casting.

our services

Sand casting is a traditional and widely used technique for creating metal components. Sand Casting offer versatility and flexibility, as it can be used to create complex shapes and accommodate various sizes. It is commonly employed in the production of automotive parts, marine parts, industrial machinery components and other metal objects.

Sand Casting

Melting

The melting process is a fundamental step in metalworking industries, enabling the transformation of raw materials into a more workable and versatile state, ready for further manufacturing processes.

CNC Machining

CNC machining is widely used in industries such as aoerospace, automotive, electronics and medical, where precision and quality are paramount. It offers increased productivity, versatility and the ability to manufacturing parts with exceptional accuracy and consistency.

Compare to traditional methods such as mechanical grinding or chemical teatments, laser derusting offers several benefits. It is a non-contact and non-abrasive process, minimizing the risk of surface damage. It also eliminates the need for harsh chemicals or manual labor, resulting in a cleaner and more environmentally friendly rust removal method.

Laser Derusting

3D Precision Printing

3D precision printing is a cutting-edge technology that enables the creation of highly accurate and intricate three-dimensional objects. It involves the layer-by-layer deposition of materials based on digital designs, resulting in the fabrication of complex geometries with exceptional precision.

quality policy

Sama Mahir strive to be the most reliable, competitive and innovative manufacturer for the oil & gas, marine parts, automobile, machine builders, semicon and petrochemical industries by the following policies:-

We will always produce superior quality products and provide best customer service.

We are committed to total quality management concept and continually improvement program.

Do right the first time and achieve higher productivity.

hse policy

Design facilities, establish practices, provides training and conduct operation in a manner that safeguard

workers / contractors, properly and the communities in which it operates.

Respond quickly, effectively and with care to emergencies or accidents resulting from its operations, cooperating with industrial organization and authorized government agencies.

Comply with all applicable laws and regulations and apply responsible standards of its own where laws and regulations do not exist stress to all employees / contractors, their responsibilities and accountability for safety and helth performance.

Undertake appropriate reviews and evaluation of its operations to measure progress and to ensure compliance with this safety and health policy.

environmental policy

Sama Mahir commited to protect the environment by reducing the present and future environmental risk of its business operations.

Our environmental policies is...

Minimize Environmental Risks of our business operations.

This means that Sama Mahir is committed to...

- Complying with all applicable environmental laws and regulations.

- Investigating and controlling the impact of hazardous releases to the environment.

- Continually improving operations which could have a significant impact on the environment educating associates to be responsible environmental stewards through recycling.

- Conserving resources and ultimately climinating waste and the environmental risks of our business operations.

equipment overview

- Aluminium Induction Furnace x 1

- Inductotum Ferrous Induction Double Body x 1

- Aluminium Resistant Continuous Melting Furnace x 3

- Annealing Induction Furnace x 1

- Copper Alloy Induction Furnace x 1

- Sand Blasting Machine X 1

- Gravity Die Cast Machine x 1

- Squeeze and Joint Molding Machine x 5

- Sand Mixing Machine x 2

- CNC Milling Machine x 4

- CNC Lathe Machine x 2

- Manual Lathe Machine x 4

- Laser Derusting Machine x 1

- Grinding Machine x 1

- Keyway Machine x 1

- Coordinate Measuring Machine (CMM) x 1

- Portable Hardness Tester x 1

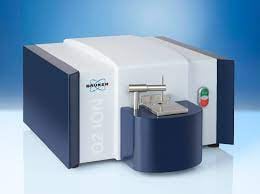

- Metal Tester Spectrometer x 1

business partners

Our business partners play a vital role in our journey. They bring unique perspectives, specialized knowledge and valuable resources to the table, enhancing our ability to deliver exceptional products and services to our customers.

contact us

+607-380 6928

general@samamahir.com

NO.8, JALAN SRI PLENTONG 6,

KAWASAN PERINDUSTRIAN SRI PLENTONG,

81750 MASAI, JOHOR, MALAYSIA.